Why do inspections make a difference?

Workplace inspections are one of the easiest and most effective ways to keep people safe. They help find hazards before anyone gets hurt, start open conversations about safety, and show workers that their well-being is important. They’re not about blame. They’re about taking a careful look at how the work is really done, then fixing what could hurt someone.

When done the right way, inspections can do much more. They can build trust, prevent injuries, and create a workplace where everyone feels supported.

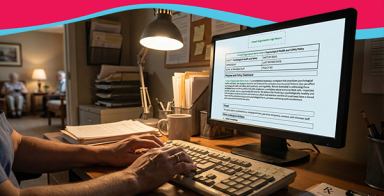

Download our inspection checklist to get started.

When and how should inspections occur?

Inspections should be done on a regular basis, depending on the type of work and the level of risk. Employers or supervisors usually lead them, but your safety committee or worker safety rep should be involved. It’s also smart to invite workers from different roles. People who do the work every day often notice things others miss.

Some inspections are formal. They follow a planned process. Others are informal, like when a worker sees something unsafe and speaks up. Both are important.

What to check before, during and after an inspection

Look at both the big picture and the small details. Pay attention to:

- Structures and surroundings: buildings, rooms, exits, outdoor paths and entrances

- Equipment and tools: lifts, belts, carts, beds, and furniture

- Work methods and practices: how work is done, how things are stored, cleaning, and safety routines

Also check everyday basics, such as protective gear, ergonomics, first aid supplies, emergency plans, hazardous products, lighting, flooring, noise levels, and walkways.

Before you start

A good inspection begins before you enter the work area.

- Review past inspection reports and incidents. What still needs fixing?

- Plan your route and who will cover each area.

- Bring a toolkit: floor plan, checklist, method to record findings (phone, tablet, or paper), camera, proper clothing, and any necessary PPE.

- Let the area supervisor know you’re coming.

While you’re on the floor

- Take your time and look everywhere: up, down, inside, and around. Don’t skip areas just because they are awkward or busy.

- Ask workers what slows them down or creates hazards. Listen for details about how the work is done.

- If you see an immediate danger, fix it if you can (for example, put out a wet floor sign, remove a broken step stool, or lock out broken equipment) and tell the supervisor.

- Record everything, even if you fixed it right away.

After the walk-through

- Write your findings clearly. Share them with the supervisor, employer, and safety committee or rep.

- Prioritize issues: what needs fixing, who’s responsible, and the deadline.

- Follow up to make sure the fixes happen.

Inspections show workers that safety is taken seriously. Over time, they make the workplace safer and build confidence for everyone.

Training matters too

Training is another key piece. Inspectors need to know not just what to look for, but why it matters. They need to understand hazards, how rules apply, and how to talk to staff. A good inspection is not just about looking at equipment or rooms but also engaging with workers. Workers can point out risks that might not be obvious. Pairing new inspectors with experienced ones helps them learn what to look for and how to ask the right questions. Following WorkSafeBC guidelines also helps make sure inspections are done correctly.

Turning inspections into real change

An inspection only works if change follows. Reports should be clear, shared quickly, and used to spot trends. This could mean more training or creating new Safe Work Procedures. Track whether fixes are completed and keep workers informed.

There should be a way to track whether fixes are completed, and workers should also be informed of the results. When people see that their concerns lead to real changes, they are more likely to stay involved and help in future inspections.

The best workplaces treat inspections as part of everyday work, not just something that happens occasionally. Inspections should be moments to pause, check how the job is being done, and make sure everyone gets home safe.

To see real examples of what to include on an inspection checklist, look at our workplace inspections safety huddle. Home support workers can also take advantage of our safe driving checklist.

If your safety committee members want to build their inspection and investigation skills, they can take our Safety Committee Part Two – Beyond the Basics course. This course is for those who have already completed Part One. It covers key topics like hazard identification, risk assessment and controls, effective inspections, and investigations.

Register now to strengthen your safety committee’s skills